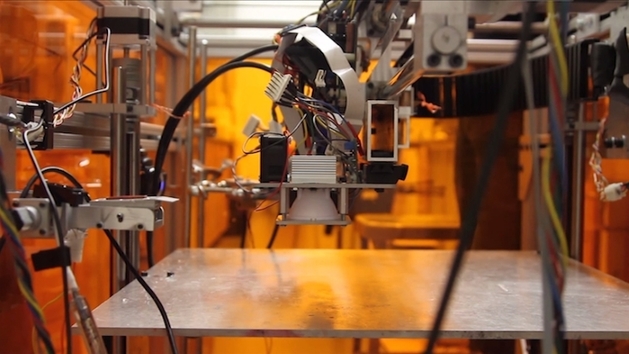

The MultiFab 3D printer prints up to 10 different materials at once, saving users time, energy, and money.

Sourced through Scoop.it from: www.pcmag.com

Whether you’re building a footbridge or a sports car, 3D printing can be a cheap and easy way to obtain the materials you need. But it has its limits. Most 3D printers use one material at a time, though some pricey machines have dabbled with up to three materials. But a team of researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) developed the MultiFab 3D printer, which prints up to 10 different materials at once. – Using 3D-scanning techniques, the MultiFab can self-calibrate and self-correct. It also allows users to embed complex components (i.e. circuits and sensors), directly onto the body of an object; the researchers, for instance, printed lenses on top of LEDs. Unlike most current 3D printers, the MultiFab can produce and finish a product—moving parts and all—in one fell swoop: Place an iPhone into the printer, and it will spit out a perfectly sized case, the team said. While the CSAIL team has no expectations of their MultiFab 3D printer being installed in customers’ homes, they do hope it can be put to use by researchers, manufacturers, and other businesses. “Picture someone who sells electric wine openers, but doesn’t have $7,000 to buy a printer like this,” Ramos said. “In the future they could walk into a FedEx with a design and print out batches of their finished product at a reasonable price. For me, a practical use like that would be the ultimate dream.”